Enhancing Operational Efficiency and Building a Future-Ready Water Infrastructure VA SYD, the regional water utility in Skåne, Sweden, has partnered with Waltero to revolutionize its water inlet monitoring and maintenance. This collaboration leverages Waltero’s cutting-edge camera-equipped W-Sensors and the intelligent Mimir cloud platform, implemented through a strategic phased plan. The result? VA SYD is achieving significant operational savings and laying the groundwork for a truly predictive, scalable, and resilient water infrastructure management system. This case study highlights a successful partnership, beneficial to both VA SYD and Waltero, demonstrating a clear path to modernized utility operations.

Background & Objectives:

The Challenge of Traditional Monitoring

Maintaining thousands of water inlets has traditionally demanded frequent, time-consuming physical inspections to check for debris blockages and monitor water levels. These tasks become even more challenging and critical during unpredictable weather events. VA SYD recognized the need for a more efficient, proactive approach to:

- Reduce Operational Overhead: Minimize the labor, fuel, and time associated with manual

inspections. - Improve Response Times: Address potential problems faster to prevent severe blockages

or flooding. - Enhance Overall Infrastructure Management: Move from a reactive to a predictive

maintenance model.

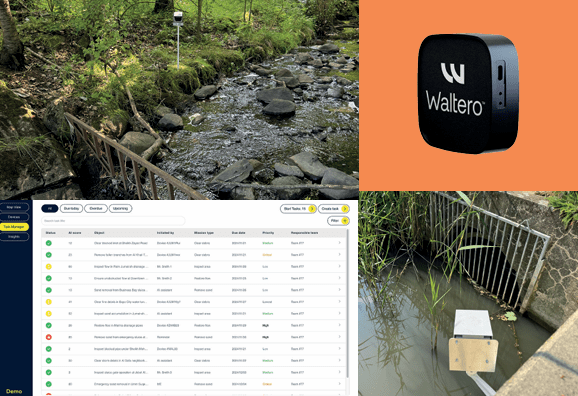

Waltero’s W-Sensor, paired with their Mimir platform, offered the ideal solution: consistent imagery and machine learning (ML) analysis that could fundamentally shift maintenance from reactive to preventive. VA SYD actively drove the solution forward, integrating their system with Waltero’s Mimir platform to unify infrastructure data and automate decision making.

“We have a good collaboration with Waltero, and their product has already provided significant benefits to our operations at an early stage. Our team is now able to perform visual inspections from the office instead of having to drive out to the monitored facilities.”

– John Hägg, Development Engineer, VA SYD

Three Phases of Implementation: A Roadmap to Success

The partnership between Waltero and VA SYD was structured around a pragmatic, three phase implementation plan, ensuring continuous learning and optimization at each step.

Phase 1

Image Collection

Phase 2

Smart Insights

Phase 3

Predictive

Monitoring

W-Sensors are

deployed to capture

initial image data from

water inlets. This phase

focuses on gathering

visual intelligence and

learning from real-world

conditions, providing

immediate remote

visibility

Building on collected

data, Waltero’s AI trains

to automatically extract

actionable metrics

like water depth and

blockages. This enables

intelligent, automated

alerts for faster

response and better

resource allocation.

As our AI matures,

it will dynamically

adapt monitoring

frequency and predict

future blockages.

This phase empowers

strategic decision

making and optimal

resource deployment

across the entire water

infrastructure.

Phase 1: Remote Visual Inspections & Environmental Learning

The initial phase focused on deploying W-Sensors at selected water inlets to gather

foundational image data and learn from real-world field conditions. Images were uploaded

to Mimir for manual annotation and baseline analysis, feeding directly into VA SYD’s system

for immediate utility. This phase was crucial for both data collection and strategic discovery.

Key Discoveries and Learnings:

- Immediate Value of Visual Data: Even without full AI automation, remote access to

images drastically reduced inspection trips. - Dynamic Nature of Blockage: Observations revealed that blockages could form

either at the waterline or from debris accumulation at the base, requiring

comprehensive monitoring. - Optimal Camera Positioning: A wider view, positioned at a distance from the grid, was

essential for maintenance teams to get a full overview and avoid interfering with

cleaning routines. - Varying Monitoring Needs: Daily daytime images sufficed for routine checks, while

heavy rainfall demanded hourly, 24/7 monitoring. - Hardware Demands: Sensors required 3-5 year battery life and robust optics to

perform in all conditions (direct sunlight, low light, total darkness).

Operational Results from Phase 1:

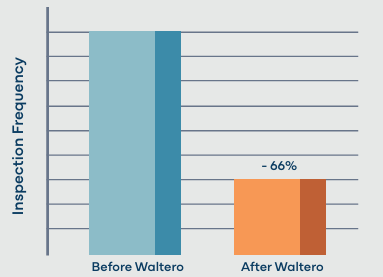

- Routine inspections reduced by -66%, leading to substantial savings in labor and transportation.

- Maintenance teams gained the ability to review inlet conditions remotely, improving efficiency.

- A solid foundation was laid for smarter hardware and AI models in subsequent phases.

Phase 2: Sensor Upgrades & Smart Insights (Current Stage)

Leveraging the invaluable feedback from Phase 1, Waltero and VA SYD implemented significant hardware and software upgrades. This phase is currently focused on training Waltero’s ML model to automatically extract actionable data from images, enabling custom thresholds for automated alarms.

Hardware Enhancements:

- New Weather-Resistant Casing: Enhanced durability for all outdoor environments.

- IR Lighting: Ensures clear imaging in low-light and total darkness conditions (e.g., wells).

- Higher-Resolution Cameras: Provide the detailed input required for advanced ML analysis.

- Upgraded Battery Modules: Extend deployment cycles for longer uptime and fewer maintenance interventions.

In Parallel, Software Updates Were Deployed Remotely:

- Virtual Ruler: Enables precise measurement of water levels and rising speeds directly from images.

- API-based Rescheduling: Allows smart adjustments to monitoring frequency based on real-time weather forecasts.

Key Benefits Realized in Phase 2:

- Automated water depth and blockage detection via ML.

- Customizable alarms triggered when predefined thresholds are breached.

- Faster reaction times for remote teams, allowing for prioritized site visits base on real-time data

Phase 3: Predictive Monitoring & System Optimization (Future)

As the volume of image data accumulates and the ML model matures, Phase 3 will unlock highly sophisticated predictive capabilities. This will enable VA SYD to move beyond reactive and even proactive, into truly predictive maintenance.

Capabilities in Development:

- Adaptive AI: Dynamically adjusts image frequency based on weather forecasts and previous anomaly detections.

- Subtle Pattern Detection: AI will learn to predict where and when blockages are likely to occur.

- Prioritization Engine: Recommends where to send teams across the entire region based on risk levels and predicted needs.

Anticipated Outcomes from Phase 3:

- Region-Wide Insight: Enables strategic decision-making for infrastructure planning.

- Automated Scheduling: Site checks are tied to risk levels, optimizing resource deployment.

- Better Use of Resources: Longer asset life and significantly reduced emergency repairs, contributing to overall sustainability.

Early Results & Outlook: A Partnership Driving Real Value

The collaboration between Waltero and VA SYD has already delivered tangible benefits and

promises even greater efficiencies in the future.

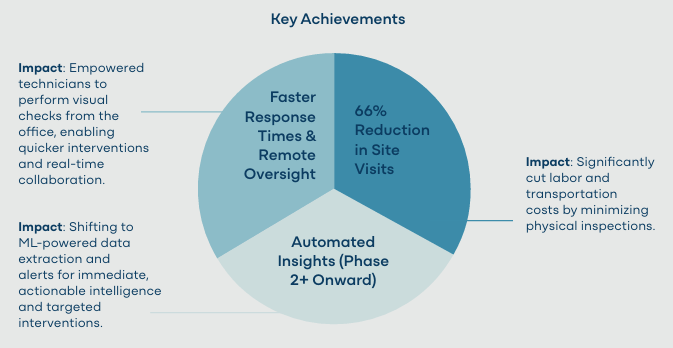

- Operational Savings: Even in Phase 1, on-site maintenance runs decreased by a remarkable 66%, leading to substantial cuts in labor and transportation costs.

- Remote Monitoring: Technicians can now perform most visual checks from their desktops, dramatically improving response times and enabling real-time collaboration.

- Automated Insights (Phase 2+): As the project moves into Phase 2, ML-powered data extraction will empower teams with immediate, actionable intelligence, leading to even fewer site visits and more targeted, efficient interventions.

- Scalable and Future-Ready: With Phase 3 on the horizon, VA SYD will gain deeper, predictive insights, allowing for agile adaptation to changing conditions and system wide management priorities, paving the way for smarter city infrastructure.

Through this phased, collaborative approach, VA SYD is transforming its operational model from reactive to proactive and ultimately, predictive. Waltero’s camera-equipped W-Sensors and AI-driven Mimir platform are unlocking new efficiencies, providing deeper insight into water inlet conditions, and conclusively strengthening Skåne’s water infrastructure for the

future. With each phase, the utility is becoming not only more efficient but more resilient, proactive, and future-focused. This partnership stands as a testament to the power of modernizing essential public services.