Introduction

At Waltero, we’ve seen firsthand how the demands of industrial operations, especially in oil, gas, utilities, and manufacturing, have outgrown the capabilities of manual monitoring. We believe it’s time for a smarter approach, asset monitoring that leverages computer perception and Edge AI cameras to watch equipment, capture trends, and flag issues before they escalate.

From remote oilfields to urban substations, teams are still relying on people with clipboards to track the health of mission-critical equipment.

In this post, we’ll walk through the top five real-world use cases where Edge AI and computer vision are already transforming how industries handle asset condition monitoring, remote asset monitoring, and more. Let’s explore where the future is happening right now.

Why Asset Monitoring Needs an AI Upgrade?

Asset monitoring is the process of remotely tracking physical assets using specialized hardware and software. Asset monitoring solutions based on IoT technology provide accurate real-time information, while traditional asset monitoring practices rely heavily on manual inspections and static sensor systems. However, in fast-moving industries such as energy, manufacturing, and infrastructure, outdated methods can lead to blind spots, delayed responses, and missed opportunities.

Today’s asset monitoring systems require:

- Real-time visibility into asset health and performance

- Scalable monitoring solutions for both digital and analog infrastructure

- Smarter alerts and analytics that reduce downtime and improve safety

That’s where asset monitoring AI and computer perception come in, transforming asset tracking.

How organizations track assets, gather, interpret, and act on asset data. These technologies enhance industrial asset monitoring, making it possible to track equipment from remote oil rigs to urban utility substations.

By integrating Edge AI cameras, companies get:

- Automated visual inspections of analog gauges, meters, and indicator lights

- High-value asset monitoring without the need to replace old meters

- Scalable asset performance monitoring across thousands of points of interest

This is not just an upgrade, it’s a new standard for asset tracking and efficient asset management.

Why Advanced Asset Tracking Software Is Essential for Modern Asset Monitoring?

Asset tracking is the practice of monitoring the location of an organization’s physical assets to maximize efficiency and minimize loss. When it comes to managing industrial equipment at scale, traditional methods fall short to track assets. That’s why organizations are turning to smarter asset tracking software and integrated asset tracking systems that work hand-in-hand with Edge AI and computer perception.

Today’s top-performing asset tracking solutions go far beyond GPS or barcodes—they incorporate computer vision-based asset tracking technologies that can visually confirm gauge readings, valve positions, or indicator light statuses. This creates a digital trail for every event and adds visual intelligence to standard tracking methods.

Whether it’s a medical facility, a manufacturing plant, or a utility, an asset tracking solution provides visibility and control by ensuring near-real-time data insights about your asset health and levels. Leading towards enhanced utility data management.

Here’s how companies are using these tools for asset tracking more effectively:

- Combining Edge AI cameras with asset tracking software to automate logs of analog and visual asset data insights.

- Using a unified asset tracking system to manage everything from utility meters to safety devices.

- Applying asset tracking solutions in remote environments where standard IoT sensors fail.

- Leveraging asset tracking technologies to cross-check visual conditions with sensor data, creating redundancy and reliability.

- Implementing vision-based alerts to track assets that show visual signs of malfunction or wear.

For any operation looking to track assets at scale, especially high-value or safety-critical ones, a modern asset tracking system merged with Edge AI and IoT is becoming indispensable.

Asset Management Software Transforming Enterprise Asset Health Monitoring at Scale

As industrial operations grow in scale and complexity, asset management has become a cornerstone of operational resilience. Companies are no longer just tracking physical assets—they’re investing in technologies that improve asset health visibility, reduce downtime, and extend equipment life. That’s where modern asset management software makes a major impact for efficient operations.

In the age of smart infrastructure, enterprise asset management is about more than Excel spreadsheets or scheduled maintenance. Organizations now need tools that can monitor asset health in real time, aggregate insights across facilities, and adapt dynamically as operations evolve. At Waltero, we believe computer perception and Edge AI bring new power to enterprise asset management by enabling continuous, visual oversight of analog and digital indicators alike.

By combining intelligent camera-based sensors with robust asset management software, teams gain actionable insights into asset health, from remote oil pipelines to critical building systems. Whether you’re managing 500 devices or 50,000, a scalable asset management strategy paired with Edge AI and IoT allows more informed decisions, faster response times, and truly proactive rather than reactive asset health monitoring. The future of enterprise asset management in action.

1. Use Case 1: Remote Oil & Gas Facility Asset Monitoring

The Challenge:

Remote wellheads, pipelines, and storage tanks often have analog pressure or flow gauges, but sending humans to read them is dangerous and expensive.

The Solution:

By installing Edge AI cameras with computer perception, companies can monitor multiple analog gauges on-site, 24/7. These cameras are rugged and capable of interpreting analog dials using vision algorithms. They operate near real-time and can push alerts if values exceed the safe range.

At Waltero, we are enabling digitization in utilities, turning retrofit gauges for oil & gas into smart meters. One camera can digitize pressure, temperature, or flow values and feed them directly into a SCADA or asset monitoring system.

The Results:

- Prevent spills or blowouts by catching anomalies early

- Cut field technician visits and associated costs

- Enhance safety by reducing worker exposure in hazardous areas

Real Example: A global oil & gas operator deployed over 3,500 battery-powered smart cameras at 500+ remote sites to replace manual inspections, reducing field visits while improving operational visibility.

2. Use Case 2: Monitoring Utility Substations and Transformers

The Challenge:

Utility companies still rely heavily on manual rounds to check temperature gauges, pressure dials, and breaker positions in substations.

The Solution:

Edge AI cameras continuously observe these indicators, replacing clipboard rounds with automated visual checks. Computer perception allows these cameras to monitor:

- Transformer oil temperature gauges

- SF6 pressure indicators

- Breaker switch positions

These cameras send readings to an asset monitoring system and alert operators if anything falls outside of normal parameters.

The Results:

- Improve asset health monitoring and grid reliability

- Avoid unplanned outages from missed anomalies

- Reduce manual inspection labor and risks in high-voltage areas

Case Study Insight: Studies show that using Edge AI for substations helps utilities monitor legacy analog systems without the need for expensive digital upgrades.

3. Use Case 3: Manufacturing Plant Equipment

The Challenge:

Legacy manufacturing equipment still relies on analog pressure, temperature, and fluid level gauges that must be read manually.

The Solution:

Edge AI cameras can read data from multiple gauges.

Solutions like the W-Sensor offer battery-powered, LTE-connected cameras that last for more than 8 years. These can feed data into asset condition monitoring software or predictive maintenance platforms that can track asset health.

This visual data allows plant managers to:

- Identify deteriorating equipment early

- Reduce downtime

- Digitally log gauge readings for compliance or auditing

The Results:

- Scale asset tracking and monitoring assets remotely to hundreds of gauges without having to replace old meters.

- Feed visual data into asset performance monitoring platforms.

- Enable smarter decisions based on data.

Example: One factory scaled from a pilot to 2,000 AI cameras across 320 sites, automating analog gauge reading for boilers, compressors, and more.

4. Use Case 4: Facility Management (HVAC and Utilities in Buildings)

The Challenge:

Many buildings still rely on staff to manually record water, gas, steam, or electricity meter readings in basements or mechanical rooms.

The Solution:

Edge AI cameras with computer perception can automatically read and digitize:

- Utility meters (water, gas, electric)

- Boiler pressure gauges

- HVAC system indicators (e.g., chiller levels)

This turns analog infrastructure into part of a smart building monitoring system without needing smart meters.

The Results:

- Save labor costs on routine inspections

- Identify issues early (e.g., leaks)

- Automate logs for billing or maintenance records

Bonus: Visual logs allow facility managers to audit meter readings and compare usage trends over time, increasing energy efficiency and compliance.

5. Use Case 5: Safety Compliance Inspections

The Challenge:

Fire systems, safety showers, and emergency equipment often require visual checks to confirm gauges are in spec or indicator lights are green. Manual inspections are error-prone and inconsistent.

The Solution:

Computer vision can monitor:

- Fire system pressure gauges

- Safety shower tank levels

- Status indicator lights (e.g., green = normal, red = fault)

Edge AI cameras perform automated visual inspections, logging values, and sending alerts for anything out of compliance. They provide visual evidence for audits and reduce human oversight errors.

The Results:

- Ensure high-value asset monitoring for safety-critical systems

- Create a digital audit trail with timestamped images

- Catch faults before they result in fines or danger

Example: A chemical plant used AI cameras to inspect emergency shower gauges daily, instead of relying on weekly clipboard checks. Faults were caught within 24 hours instead of going unnoticed for days.

Market Trends: Where Industrial Asset Monitoring Is Headed

The global AI camera market is projected to grow significantly, from $12.4 billion in 2025 to $78.7 billion by 2034, fueled by the rising demand for automation, operational efficiency, and safety across industrial sectors. Despite the surge in digitalization, analog systems remain deeply embedded in oil & gas, utilities, and manufacturing environments, making visual-based asset monitoring solutions not just relevant, but essential for bridging the digital gap.

To meet these needs, companies are rapidly shifting toward modular Edge AI platforms that support a wide range of use cases, from analog gauge reading systems and leak detection to compliance verification and predictive maintenance. These platforms offer flexibility and cost-efficiency, especially in environments where retrofitting with traditional IoT sensors is impractical.

Market adoption is accelerating fastest where AI camera systems are easy to deploy, such as battery-powered and LTE-connected devices, and can seamlessly integrate with existing asset monitoring platforms. These characteristics make Edge AI an ideal solution for organizations seeking scalable, non-invasive upgrades to their enterprise asset monitoring strategies.

Key Challenges in Asset Monitoring

While asset monitoring technologies have advanced rapidly, many organizations still face significant hurdles that hinder full-scale adoption and performance. In order to build a more resilient and efficient monitoring strategy, understanding these core challenges is essential:

- Analog Legacy Systems: Retrofitting is costly, but full sensor upgrades are even more expensive.

- Labor-Intensive Inspections: Staff shortages and rising costs make manual inspections unsustainable.

- Compliance Pressure: Safety and environmental compliance logs are mandatory but time-consuming.

- Data Gaps: Without real-time monitoring, trends go unnoticed until a failure occurs.

How Waltero’s W-Sensor and Mimir Cloud Platform Solve High-Value Asset Monitoring

To make asset tracking seamless and cost-effective. At Waltero, we’ve built our solution from the ground up to tackle one of the most persistent industry pain points: the lack of scalable, reliable insight into high-value assets across industrial environments.

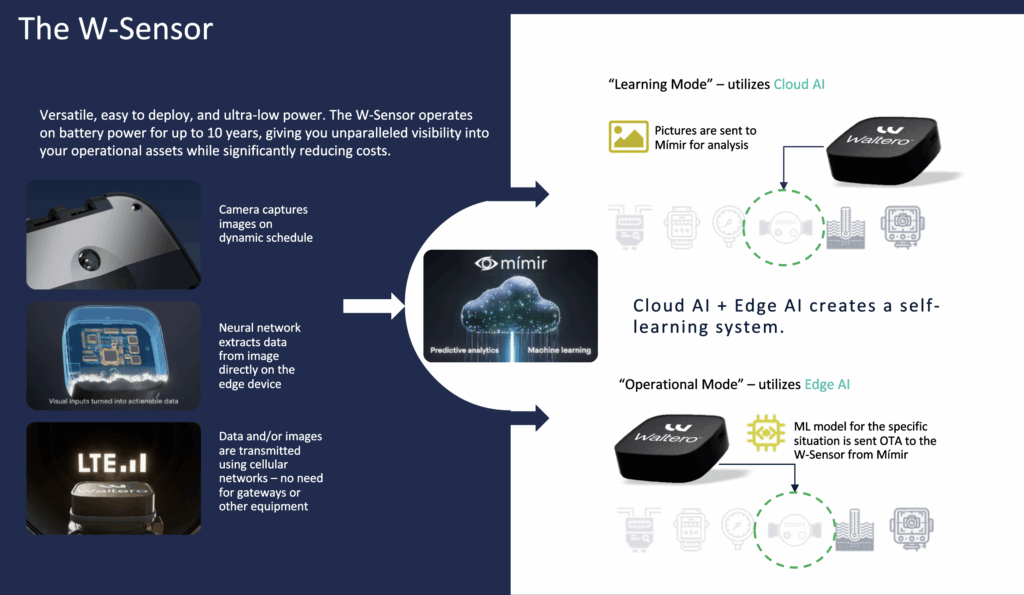

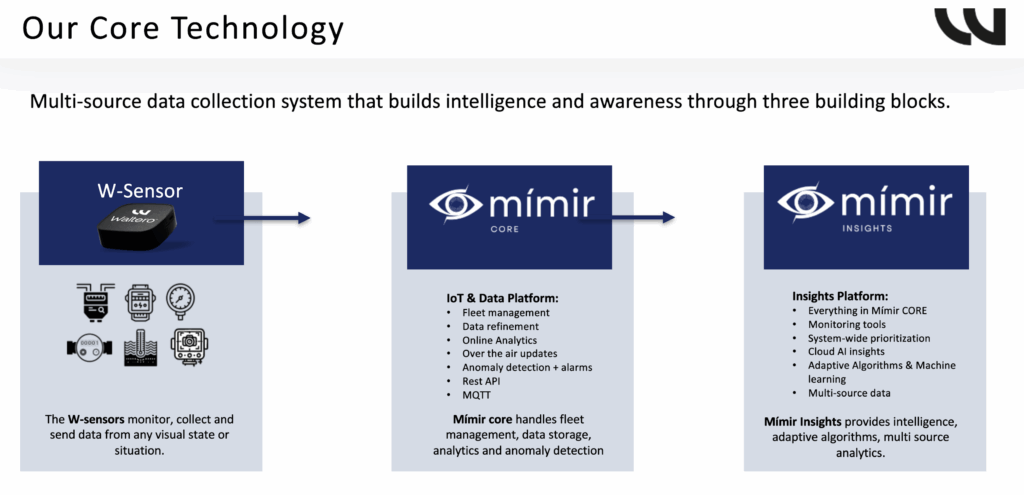

Our approach combines two powerful components:

- The W-Sensor: A compact, high-resolution Edge AI visual sensor designed for rugged industrial use. It can read analog gauges, water meters, pumps, detect valve states, interpret indicator lights, and more, all without modifying existing equipment or interpreting the ongoing working process.

- The Mimir Cloud Platform: Our secure, cloud-native environment for ingesting, analyzing, and visualizing asset data. Mimir connects seamlessly with the W-Sensor to provide actionable alerts, digital logs, and performance trends.

Together, they enable the W-Solution:

- Real-time asset condition monitoring even in remote or disconnected locations

- Automated visual inspections that reduce manual labor and improve safety compliance

- Centralized remote monitoring across multiple facilities from a single dashboard

- Predictive alerts and asset tracking without sensor retrofitting or rewiring

One of the most exciting aspects of modern asset monitoring is how seamlessly it can scale, thanks to advances in Edge AI cameras and computer perception. Whether you’re managing five sites or five hundred, the right architecture can adapt to your asset landscape without requiring massive infrastructure changes. Battery-powered Edge AI cameras enable rapid deployment, even in locations with no existing power or network. LTE and wireless capabilities eliminate the need for trenching or cabling, making remote monitoring both feasible and cost-effective. Flexible asset monitoring software captures and centralizes all data, whether visual, analog, or digital.

Even better, computer vision models can be updated remotely, allowing organizations to support new asset types or inspection criteria without hardware changes. From small-scale pilots to enterprise-wide rollouts, companies are implementing solutions that deliver faster ROI, easier transitions from testing to production, and long-term infrastructure modernization. By targeting key pain points like manual gauge readings, safety compliance, or lack of remote visibility, teams are laying the foundation for scalable, intelligent asset monitoring across their operations.

Our Perspective: Where the Industry’s Going (And Why We’re Excited)

At Waltero, we see enormous promise in computer perception and asset monitoring AI, not just for automating data collection, but for fundamentally changing how we interact with assets. Instead of sending someone to check on equipment, we’re training machines to be our eyes, capturing visual context and turning it into action.

What’s most exciting is the versatility of this approach. One Edge AI camera might start by reading a steam gauge, and later be trained to detect an oil leak, recognize a warning light, or track door position.

This adaptability is the real breakthrough. Whether it’s industrial asset monitoring, remote pipeline inspections, or facility automation, smart cameras give organizations a scalable, cost-effective tool for asset condition monitoring and beyond.

Whether you’re managing pipelines, substations, or sewage systems, gas & oil flow meters, Waltero’s solution ensures you’re not just watching your assets. You’re understanding them, acting on data, and improving performance in real time, all while maintaining vital asset health and asset lifecycle, thus reaching operational efficiency.

Apply for Waltero’s Exploratory Kit – Smart Metering Technology to see how visual AI can modernize your operations.

Conclusion:

Computer vision and Edge AI are rapidly becoming essential tools for modern asset monitoring. By digitizing analog systems, improving safety, improving asset health, and unlocking near-real-time insights. These technologies are helping teams do more with less and do it smarter.

From remote oil wells to commercial buildings, asset-rich organizations are turning to asset monitoring software and Edge AI platforms to close the data gap without massive retrofits. Whether you’re trying to reduce maintenance costs, boost safety, or just gain better visibility into your operations, the opportunities are clear.

Let’s put smart eyes where they matter most.

Johan Nordén – Vice President Research & Development, Waltero

With a PhD in Optics and Solar Energy and years of applied experience in computer vision, Johan guides Waltero’s technical roadmap for AI-powered analytics across edge, on-prem, and cloud environments. His deep knowledge of imaging systems and optical technologies ensures that our monitoring and vision solutions deliver unmatched precision and operational impact.