9 Types of Flow Meter: Uses, Pros, Cons, Integration

Hichem Kraiem

Growth ManagerIntroduction

Whether you’re dealing with water treatment, chemical processing, or any other industry where precise fluid measurement is vital, this guide will help you navigate the nuances of various flow meter technologies.

We’ll cover the unique advantages, potential drawbacks, and ideal applications for each type of flow meter, providing you with the knowledge to make an informed decision that optimizes your operation’s performance.

Understanding Flow Meters: The Basics

Welcome to the domain of flow meters, intricately designed devices tasked with gauging the velocity of fluids—be it liquid, gas, or vapor—as they traverse through a channel or piping.

These instruments are critical for monitoring fluid dynamics within industrial settings and play a pivotal role in maintaining process efficiency by accurately quantifying fluid movement.

An essential function where precision equates to both energy conservation and disaster prevention.

The key to their dependable accuracy lies in impeccable installation.

Proper placement is crucial for avoiding any disruptions that might affect measurements negatively. Beyond mere installation lies appreciating the path taken by fluids, considering sensor orientation and its influence on data collected.

Designed for diverse needs from ongoing monitoring to total volume assessment, these sensors adeptly send indispensable data directly where needed.

In some cases, achieving consistent repeatable readings takes precedence over absolute precision—a testament to why having clarity about measurement requirements is imperative at project inception.

When assessing flow rate via these sensors, temperature and pressure aren’t just conversational points.

They’re significant variables affecting gaseous density which influences volumetric calculations accordingly hence why flow meters possess robustness able cater across extreme thermal ranges without faltering.

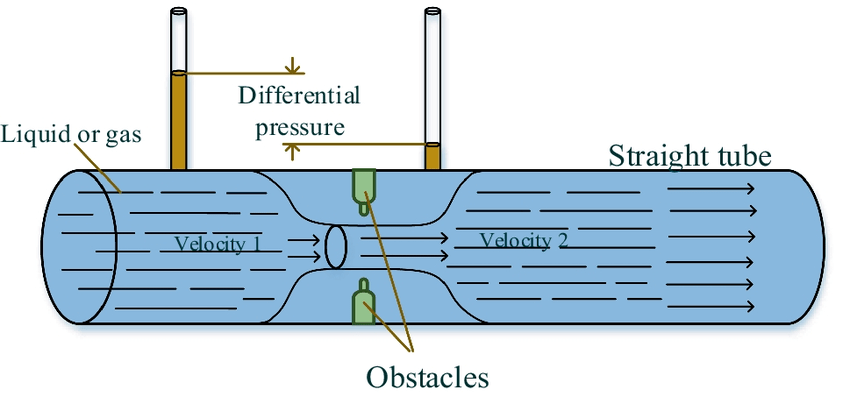

1. Differential Pressure Flow Meter

Imagine a river’s undisturbed flow suddenly quickening as it meets an array of stones, leading to a noticeable pressure fluctuation. This natural occurrence parallels the operational principle behind differential pressure (DP) flow meters.

By intentionally placing an obstruction within the pipeline, these devices create a measurable change in pressure that cleverly determines the liquid’s flow rate using Bernoulli’s Principle.

The extent of pressure reduction across this blockage correlates squarely with the fluid’s velocity, assuring both consistent and smoothly trackable flows.

These apparatuses don’t deviate from established practices.

Indeed, differential pressure flow meter measurement principles abide by ISO 5167 standards that attest to their reliability and uniformity.

From commonly used orifice plates through efficient venturi tubes down to basic pitot tubes – each style is crafted for specific roles and suited to particular scenarios without much fuss on maintenance due primarily to static part construction which allows adaptability over various use cases.

Flexibility characterizes differential pressure flow meters meters not only regarding structure but also performance-wise.

They can snugly fit into limited spaces while demanding little piping

Prove effective under high heat conditions handling diverse types of fluids

Are capable of managing non-conductive liquids—a task challenging for electromagnetic counterparts

Accommodate primary elements such as averaging pitot tubes tailored according to pipe dimensions and flowing velocities

They employ secondary components like differential pressure transmitters along with tertiary ones like temperature sensors amplifying precision at every stage.

Beyond just understanding differential pressure flow meters’ role in measuring intricate differentials in pressures adeptly—these flow meters are recognized virtuosos among other monitoring options available—one can trust them for reliable readings amidst complex environmental settings or when dealing with peculiarities inherent within varied substances being gauged.

2. Volumetric Flow Meters

Shifting our focus from pressure-based metrics to volume-centric assessments, volumetric flow meters are the virtuosos in calculating fluid speed.

With impressive dexterity, these instruments adeptly translate such velocity into the well-known metric of volumetric flow rate.

This group features a repertoire that includes distinct members—positive displacement, turbine, electromagnetic, ultrasonic and vortex flow meters—all expertly orchestrated to gauge the flow rate employing their distinctive operational principles.

These devices have experienced a technological renaissance through innovative calibration methods and novel sensing techniques that elevate their precision levels significantly. Among them:

Ultrasonic flow meters stand out due to negligible mechanical degradation thanks to having no moving components which translates into lower maintenance needs.

Volumetric Flow Meters excel with enhanced rangeability, an attribute allowing them to overcome challenges occasionally faced by differential pressure meter types.

Positive Displacement Meters may contend with complications related to pressure drops.

When scrutinizing these instruments’ specific traits, we must acknowledge their versatility as well as their crucial function across varied settings.

From the methodical cadence of a positive displacement meter’s operation or the brisk revolutions of a turbine blade — every variety offers its own special contribution.

It is this assortment that enables suitability for numerous situations. Ensuring consistent performance regardless of whether fluids move rapidly or slowly or traverse in high quantities or sparingly.

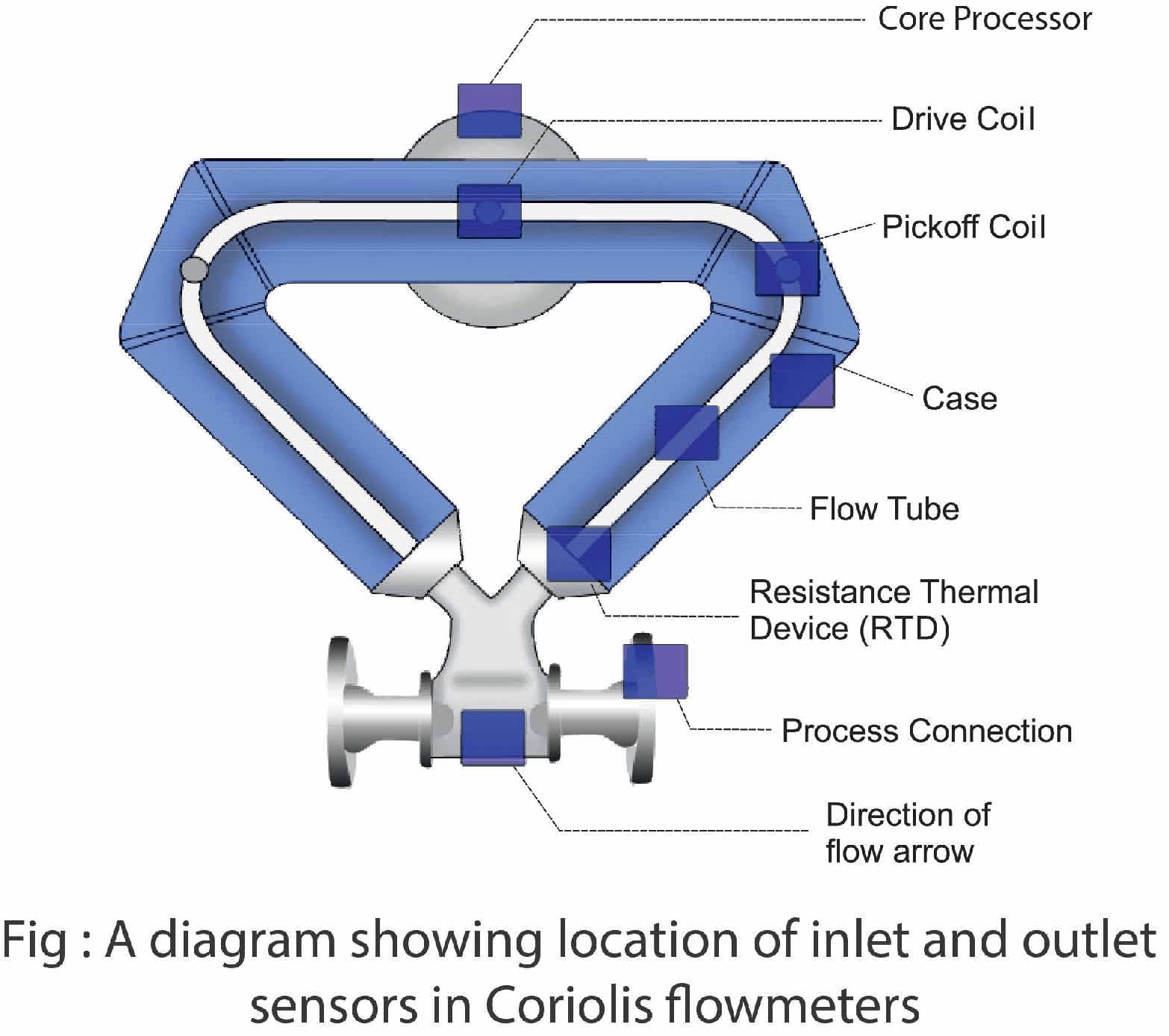

3. Mass Flow Meters

When seeking accuracy, mere volume measurements sometimes fall short.

This is where mass flow meters come into play with their sophisticated capability to determine the actual mass of fluid traveling through a device with outstanding precision.

These instruments don’t settle for just measuring volume. They delve deeper to quantify the very nature of the flowing substance, both liquids and gases alike.

It’s this commitment to comprehending the fundamental characteristics of flow that distinguishes them as vital tools in various fields.

Take into account Coriolis mass flow meters: these devices utilize the Coriolis effect for direct measurement of fluid mass flow and can even detect changes in its density.

Boasting impressive precision levels exceeding +/-0.1% along with turn-down ratios surpassing 100:1, it’s clear why industries requiring utmost accuracy consider them indispensable despite certain complexities such as:

Interference from gas bubbles within liquids which may lead to variations in readouts necessitating management for optimal preciseness.

The handling difficulties associated with high-viscosity fluids impacting meter performance which call for special accommodations.

Sensitivity toward ambient temperature shifts affecting reading reliability potentially needing correction measures.

Specific setup needs like unobstructed piping stretches before installation or proper electrical grounding essential for dependable readings.

Successfully overcoming these obstacles guarantees enhanced functioning and precise results from your Coriolis flow meters.

Alternatively, thermal mass flow meters rely on evaluating how much heat is transmitted from a heated element onto passing fluids – an indication revealing immense details about the rate at which mass flow past a point without being influenced by viscosity swings, pressure fluctuations or varying densities.

A robust method particularly accommodating towards extreme temperatures spanning icy coldness up until searing hot environments depending on each specific liquid’s ability to absorb heat.

Especially industries ranging from chemicals production over food processing all the way through pharmaceutical manufacturing often depend upon such detailed insights provided by versatile types of materials capable of evaluating broad spectrum substances reliably.

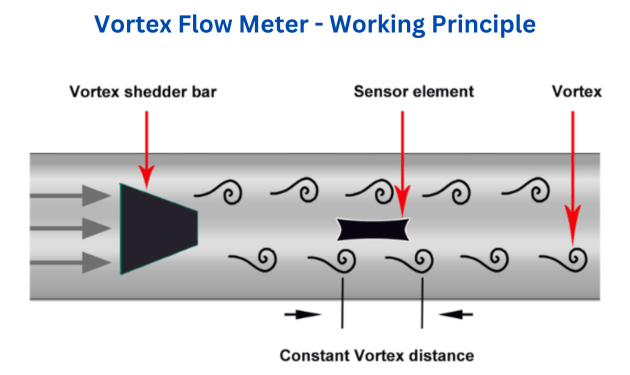

4. Velocity Flow Meters – Vortex flow meters

Let’s now shift gears and enter the vibrant world of velocity flow meters, where the fluid’s speed takes center stage. These devices take a snapshot of the fluid’s velocity at one or more points and then, like a skilled artist integrating strokes on a canvas, combine these velocity over the area of flow.

The main protagonists in this story are turbine and vortex flow meter, which, through their ingenious designs, capture the flow rate.

Velocity flow meters maintain their composure even when viscosity changes, particularly at high Reynolds numbers.

They offer a high degree of accuracy, especially with low-viscosity fluids and under laminar flow conditions, making them a reliable choice for a variety of applications.

Turbine flow meters, for instance, have found their niche in measuring the flow of liquids like petroleum, while the vortex flow meter have proven itself in handling water, chemicals, and gases.

Their adaptability extends to installation as well, with various housings designed for direct pipeline integration capable of withstanding a range of temperatures and pressures.

Moving from one meter type to another, we should identify and appreciate the unique benefits offered by velocity flow meters. Some of these benefits include:

Accurate measurement of fluid speed

Integration of fluid speed to calculate flow rate

Invaluable tool in industries where flow velocity is a significant parameter

Moving away from the rapid streams of velocity flow meters, we’re about to explore the open channels where gravity plays a dominant role, and fluid flow measurement interacts harmoniously with our world’s natural forces.

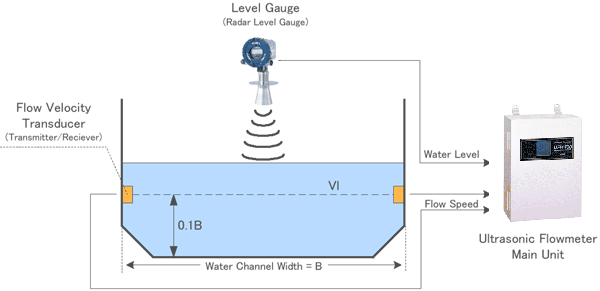

5. Open Channel Flow Meters

Delving into the expansive arena of non-contained systems, open channel flow meters emerge as the dominant technology.

These instruments employ level sensors without making contact, keeping track of liquid movement in environments free from overhead constraints—such as channels, flumes, weirs, and pipes that aren’t fully filled.

Within these spaces where gravity choreographs the fluid’s journey with both splendor and precision.

To measure flow within these settings requires a profound comprehension of fluid mechanics intricacies.

The deployment of the Manning equation is critical here. It necessitates consistent flow conditions for precise calculation of flow rates.

An open channel flow meter meticulously gauges the waterway’s structure and depth like an expert surveyor mapping out every rise and dip across their charted landscape.

Often utilized in this context are ultrasonic level sensors which act as vigilant eyes for these devices.

They provide touch-less measurements that improve accuracy and reduce the need for maintenance while allowing storage of measured data logs accessible through Modbus RTU or saved onto historical records databases – positioning them not merely as passive observers but also guardians over temporal data streams.

Navigating through various applications in measuring flows demonstrates how adeptly open-channel meters integrate with natural processes capturing intricate changes smoothly and efficiently.

Now our attention turns to embrace sonic detection technologies—the acoustic measures employed by ultrasonics—reshaping conventional methods used to ascertain liquid motion metrics.

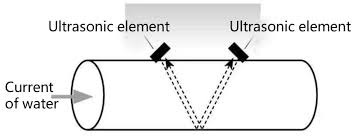

6. Ultrasonic Flow Meters

In the realm where acoustic vibrations traverse liquids, ultrasonic flow meters expertly measure fluid movement with a refined and non-intrusive approach.

These advanced instruments are primarily categorized into two groups: Doppler flow meters that reflect sound waves from particles or gas bubbles in the fluid, and Time-of-Travel (also known as Transit-Time) flow meters that ascertain the time difference of sonic pulses as they move upstream and downstream within the flow stream.

While Doppler devices are better suited to measuring flows containing suspended solids or aerated liquids such as untreated sewage, Time-of-Travel variants perform optimally in purer fluids, providing an array of industries including water purification to natural gas delivery with tailored solutions for their specific needs.

The effectiveness of ultrasonic flow measurement tools is subtly modulated by factors like:

Temperature fluctuations

Variable density

Changes in viscosity

Presence of suspended solids

Not withstanding these influences on performance measurements, clamp-on models provide a solution that does not intrude upon pipe systems. Thus enabling users to gauge liquid flows without causing significant disturbances or alterations.

Considering what ultrasonic technologies offer regarding quantifying liquid motion demonstrates their wide-ranging applicability across various types of fluids.

Now we turn our attention towards how interactions between magnetic fields and electrically conductive solutions can simplify flowing material assessments using principles rooted in electromagnetism.

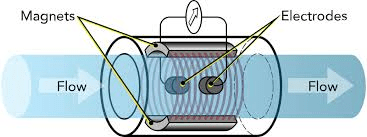

7. Electromagnetic Flow Meters – Magmeter

A magmeter, also known as an electromagnetic flow meter, operates on the principle of electromagnetic induction to measure the flow rate of electrically conductive liquids.

Essentially, it consists of a non-intrusive flow tube equipped with electrodes and a magnetic field generated by coils.

As the conductive fluid passes through this magnetic field, a voltage proportional to the flow rate is induced, which is then measured by the electrodes.

The installation process plays a vital role in ensuring the optimal functioning of these meters.

Issues like air bubbles can lead to measurement errors. Thus, correct installation is paramount for sustaining their high level of precision, which can reach within 0.5% accuracy relative to actual flow rates.

Because they are adept at measuring flows in both directions, electromagnetic Flow Meters have become invaluable across various sectors such as:

Water management

Paper production

Chemical processing

Metallurgy

And more

However, it’s important to note some limitations.

Electromagnetic Flow Meters are only suitable for fluids with electrical conductivity.

They aren’t applicable universally.

And complications like liner separation from the meters require careful selection of models to avoid potential maintenance issues later on.

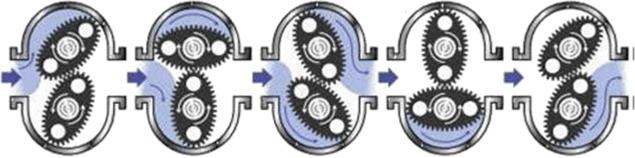

8. Positive Displacement Flow Meters

In the spectrum of flow meter types, positive displacement flow meters hold a significant niche for their systematic approach to measuring fluid flow.

They operate by entrapping small volumes of liquid within internal chambers and cycling through filling and releasing these increments with absolute precision.

This process ensures that every portion of the fluid is sequentially isolated and measured as it moves through the meter, resulting in highly accurate measurements.

Flow meters come in several forms such as:

Gear meters

Oval gear meters

Nutating disk meters

Piston meters

Each style employs its own distinctive mechanism to capture and gauge the volume of fluids passing through them.

Whether it’s via:

Helical gears engaging within a HelixGear meter,

Reciprocating motions inside a piston meter,

Interlocking oval-shaped gears functioning in an oval-gear setup

Nutating disks orbiting within their confines

All provide varied approaches for precise measurement endeavors.

Tailored especially for handling viscous liquids, charged fluids or clean gases effectively.

Positive displacement flow metros thrive across multiple uses – ranging from managing heating oils to lubricants and polymers additives among others.

With some devices claiming accuracy up to 0.1% full-scale reading combined with expansive turn-down ratios exceeding 70:1 – they are incredibly reliable though demanding routine calibration plus maintenance checks are imperative to uphold their meticulous performance standards.

It’s essential when working with these instruments to have insight into how specific factors like nature of liquid being processed can affect both operational efficiency along lifespan dramatically.

9. Volumetric Flow Meters

Volumetric flow meters, a prominent category within the flow meter family, are ingeniously designed to measure the volumetric flow rate of a fluid within a conduit.

These devices meticulously monitor the volume of fluid passing through a system over a given time, providing a direct reading of the volumetric flow.

Industries such as water treatment, food and beverage production, pharmaceuticals, and petrochemicals rely heavily on these meters to ensure consistent product quality and process control.

For instance, in water treatment facilities, volumetric flow meters are indispensable for monitoring water usage and treatment processes.

In the food and beverage industry, they are integral in proportioning ingredients and managing cleaning systems to maintain sanitary conditions.

Pharmaceutical companies utilize these meters for accurate dosing and batch control, ensuring compliance with stringent health regulations.

Additionally, the petrochemical sector employs such meters to oversee the transfer and blending of oils and chemicals, where precise volume measurements are critical for maintaining product integrity and operational efficiency.

In essence, volumetric flow meters are fit for any industry that requires meticulous control over the volume of liquids being processed, distributed, or consumed.

Their ability to provide precise volumetric flow rate data makes them an invaluable tool across a wide spectrum of applications, ensuring that processes run smoothly and efficiently while adhering to the highest standards of quality and accuracy.

Factors to Consider When Choosing a Flow Meter

The selection of a suitable flow meter is critically important to the effectiveness and efficiency of an operation.

It’s a decision that requires careful consideration, as various factors must be taken into account to ensure compatibility with the application’s unique requirements.

The characteristics of the process fluid—including its pressure, temperature, density, viscosity, and expected range of flow—are fundamental in steering your choice towards an appropriate flow meter.

While accuracy stands out as essential, it is not singular in importance.

Issues such as maintenance prospects, calibration routines, and necessary data output forms are all vital considerations when choosing a flow meter.

The location where the installation occurs is also key.

It establishes what environmental conditions will affect performance and thus determines how well measurements can be trusted when avoiding interference like vibrations or magnetic fields.

To these points mentioned above:

Required regulatory certifications

Consequences associated with system-related pressure drops

Familiarity level among plant staff concerning operation of meters

Support available from manufacturers

All these aspects contribute toward ensuring seamless integration within your system while promoting efficient and reliable long-term functionality for chosen equipment.

Waltero’s W-Sensor Solution

Striving for greater precision and user-friendliness in the realm of flow measurement, Waltero’s W-Sensor Solution stands out as an innovative force when to comes to types of flow meters.

By fusing sophisticated camera technology with the robust capabilities of AI and machine learning, Waltero is able to deliver precise interpretations for a variety of analog meter readings.

The versatile nature of the W-Sensor allows it to be effortlessly integrated into different types of meters—be they related to water, gas or electricity—and smoothly blend with pre-existing setups.

The essence of connectivity forms a pivotal aspect within the architecture of the W-Sensor system which boasts LTE, LoRa, and WiFi options making sure that data transfer remains reliable and adapts easily within our modern world filled with interconnected devices.

Yet this innovation extends beyond mere sensors.

Encompassed in what is known as Waltero’s complete W-Solution package lies full integration capability with both cloud-based services and sophisticated data management systems leading to an optimized exchange among informational databases and operational processes.

A commitment toward eco-friendly practices sees fruition through the design features imbued in every unit: each sensor promises an extensive 10-year battery life while preserving manual reading functionalities on all traditional meters thereby maintaining steadfast accuracy along with dependability.

A testament to our dedication toward customer service can be seen via their Exploratory Kit—a comprehensive assembly providing clients with everything necessary for implementation including additional resources such as specialized training programs coupled with consistent support offerings.

At Waltero we also have developed another groundbreaking element—the W-Cloud. Herein lies a multitude advanced processing tools conducive to discerning meaningful patterns from raw data points presenting users enhanced utilities like:

Immediate notifications regarding leak occurrences

Management protocols applicable on real-time datasets

An extension upon operational lifespans concerning aged analogue units

Minimization strategies aimed at overall resource depletion

Processed information directly synchronizes seamlessly onto your own designated platforms thus permitting instantaneous manipulation over collected metrics.

6 Frequently Asked Questions on Flow meters

1. What are the main types of flow meters?

Various types of flow meters exist, including differential pressure, volumetric, mass-based, velocity-related, open channel meters as well as ultrasonic, electromagnetic and positive displacement models. Each kind employs a unique technique to determine the rate at which liquid or gas passes through a system.

Types of flow meters are explained in details above in this article.

2. Why is accurate flow measurement important?

Ensuring precise measurement of flow is crucial as it impacts the effectiveness, security, and economic success of industrial processes by guaranteeing that fluids are processed or distributed in the appropriate quantities. This accuracy is essential for tasks such as administering chemical doses, billing utility services, and upholding the quality of products.

The types of flow meters you choose has a lot to do with how accurate your measurement will be.

3. Can flow meters measure both liquids and gases?

Certainly, flow meters are available that can quantify the volume of both liquids and gases. When selecting one, it is crucial to take into account aspects such as the fluid’s phase, conductivity, viscosity, and presence of particulates, which will influence your choice.

4. Do ultrasonic flow meters require the fluid to be free of solids or gases?

Indeed, for transit time ultrasonic flow meters to accurately measure flow, it is necessary that the fluid does not contain entrained gases or solids. On the other hand, Doppler ultrasonic flow meters are capable of measuring the flow in fluids even when there are suspended particles or air bubbles present. Consequently, any solids or gases within the fluid can compromise the precision of measurements taken by transit time ultrasonic flow meters.

5. How do magnetic flow meters work?

Magnetic flow meters, also known as magmeters, measure the flow rate of electrically conductive liquids using Faraday’s Law of Electromagnetic Induction. They consist of a non-magnetic flow tube with electrodes and surrounding coils that generate a magnetic field.

As the conductive liquid passes through this field, it induces a voltage across the electrodes, proportional to the flow rate. This voltage is then processed to calculate and display the flow rate, making magnetic flow meters ideal for accurately measuring the flow of corrosive, abrasive, or dirty liquids without any obstruction or moving parts.

How do mass flow meters measure and why is mass flow rate important in industrial processes?

Mass flow meters are precision instruments designed to measure the mass flow rate, which is the amount of mass passing through a cross-section of a pipe or conduit per unit time. Unlike volumetric flow meters, which quantify the volume of fluid passing through, mass flow meters measure the actual mass, providing a direct assessment of the material being processed.

This is particularly important in industrial applications where the mass flow rate can affect the quality and efficiency of the production process, such as in chemical reactions where the stoichiometry is dependent on the precise amount of reactants, or in custody transfer applications where the product is sold by weight.

Mass flow meters measure this rate by employing various principles such as the Coriolis effect or thermal transfer, depending on the type of meter.

The data they provide is crucial for maintaining consistent product quality, optimizing resource usage, and ensuring accurate billing and compliance with industry standards.

In essence, the ability to measure mass flow rate accurately is essential for any process where the mass of material is a critical parameter.

6. How does Waltero’s W-Sensor Solution enhance the functionality of existing analog meters?

Utilizing sophisticated camera technology coupled with artificial intelligence, Waltero’s W-Sensor Solution upgrades traditional analog meters. It interprets the readings precisely, delivering intelligent functionalities while supporting sustainable practices.

Conclusion

In summary, the world of flow measurement offers a variety of technologies, from the traditional differential pressure meters to modern ultrasonic and AI-enhanced sensors. Each type serves specific measurement needs.

The key to effective flow measurement is choosing the right meter for your application, ensuring accurate readings, reducing waste, and supporting environmental sustainability.

If you find yourself uncertain about which flow meter best suits your specific requirements, don’t hesitate to reach out.

We’ll provide you with the insights necessary to pinpoint the ideal meter for your application, ensuring you achieve the most accurate and efficient measurements for your unique use case.

%3Aformat(webp)&w=3840&q=75)