Achieving precise fluid measurement is a common challenge that can directly impact efficiency and cost-effectiveness.

Inaccurate flow data can lead to problematic discrepancies, causing operational headaches and financial strain. As you grapple with the complexities of fluid dynamics, it’s easy to feel overwhelmed by the myriad of measurement technologies and their limitations.

By diving into this article, you’ll better understanding on magnetic flow meters and understand how they can enhance your process control.

Understanding Magnetic Flow Meters

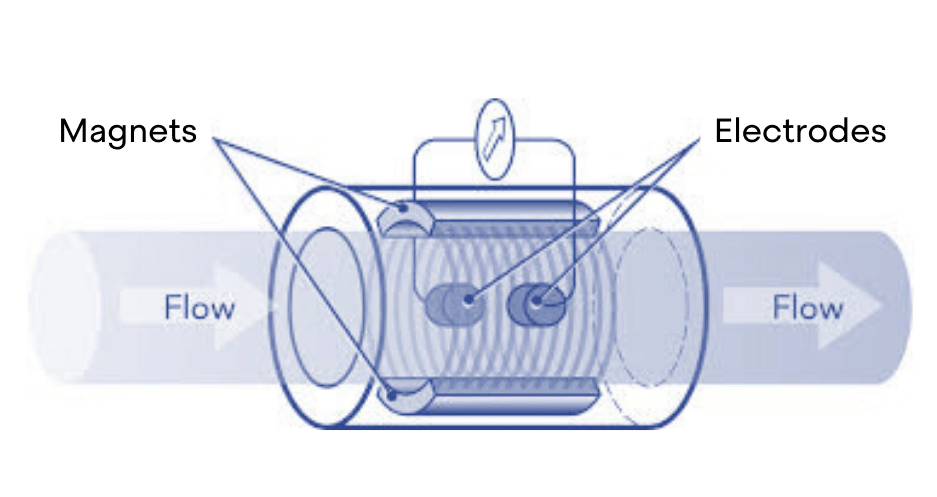

Mag meters, operate on the principle of electromagnetic induction. The fluid’s flow through a magnetic field induces a voltage across the liquid, which is fundamental to the measurement of fluid flow in these meters.

They transform the fluid velocity into an electrical signal directly proportional to the flow rate, allowing for accurate rate measurement. While volumetric flow meters measure the volume of fluid passing through, mag meters focus on the flow speed.

Designed as full-bore sensors, their internal diameter matches that of the connecting pipes, preventing fluid flow restrictions and pressure losses.

Working Principle of Magnetic Flow Meters

Mag meters operate based on Faraday’s Law of Electromagnetic Induction to measure liquid velocity.

According to this law, a conductor moving through a magnetic field produces an electrical signal directly proportional to the flow velocity of the liquid moving through the field.

For a mag meter to generate a voltage signal, the fluid passing through must be conductive.

The voltage induced by the flow of the conductive fluid within the magnetic field is captured by the flow meter’s electrodes and is then converted into a flow rate measurement by the transmitter.

Types of Magnetic Flow Meters

Mag meters come in various types, including insertion and low-flow mag meters, to cater to different measurement needs based on pipe size and flow speed.

Insertion-type mag meters are particularly well-suited for larger pipe sizes, offering an efficient solution for measuring flow in expansive piping systems.

On the other hand, low-flow mag meters are designed for small diameter pipes, typically ranging from ⅛ inch to ½ inch, ideal for applications requiring precise measurements of low flow rates.

Generally, models like the Waltero’s flowmeters are developed for compatibility with a broad spectrum of flow measurements in conductive fluids, demonstrating the versatility of mag meters in different metering situations.

Advantages of Implementing Magnetic Flow Meters

Magnetic flow meters are effective in a multitude of industrial applications due to their:

Resistance to aggressive chemicals

Adaptability to measure various liquid types

Compatibility with a range of pipe sizes and materials including plastic, metal, and concrete

This makes them extremely versatile for different installation environments.

In industries such as coal-fired power plants, these meters play a critical role in managing and measuring wastewater, ensuring environmentally compliant disposal of heavy metals.

These flow meters are instrumental in accurately evaluating water cleanliness for return to the environment, aiding in groundwater remediation efforts.

Cost Efficiency

By preventing pressure loss, magnetic flow meters help reduce operating costs, leading to lower energy consumption in the systems where they are implemented.

The cost-effectiveness of these meters is further enhanced by their durability and the fact that they require minimal maintenance over their lifespan.

However, it is still necessary to perform regular descaling and upkeep to prevent electrode fouling, which can affect accuracy.

Versatility

Magnetic flow meters are versatile instruments used across various industries including:

Water and wastewater treatment

Chemical processing

Pharmaceuticals

Food and beverage

Adaptable to harsh conditions, these meters can be equipped with specific linings such as Teflon to manage corrosive or abrasive fluids alongside their application with water-based liquids and slurries.

In water and wastewater facilities, these meters excel at accommodating the challenges of polluted, or wastewater, playing a critical role in power plant operations where water is used for cooling and steam.

Within the context of energy efficiency, magnetic flow meters contribute to cogeneration power stations located at wastewater treatment facilities by improving fuel use and managing water systems.

Selecting the Right Magnetic Flow Meter for Your Application

In the selection of a magnetic flow meter, the following factors must be considered to ensure compatibility with application process parameters:

Working temperature

Pressure

Flow rate

Velocity

A magnetic flow meter’s output can vary from a 4-20 mA analog current output, frequently used in industrial applications, to a range of digital communication outputs designed for specific application needs.

It is critical to evaluate the trade-off between cost and performance when choosing a magnetic flow meter, aiming for a solution that provides accurate, reliable flow measurement with minimal maintenance requirements.

Assessing Liquid Conductivity

Magnetic flow meters are specifically designed to measure the flow of conductive liquids and are unsuitable for non-conductive substances like gaseous materials.

For a liquid to be effectively measured by an electromagnetic flow meter, it must have a minimum conductivity of 10 μS/cm.

Using electromagnetic induction, electromagnetic flow meters, also known as electromagnetic meters, achieve high accuracy when measuring the flow of conductive fluids, irrespective of fluid density, viscosity, or pressure.

Temperature and Pressure Ranges

Temperature and pressure changes can affect the performance and accuracy of magnetic flow meters, potentially necessitating temperature or pressure compensation.

It is crucial to select a magnetic flow meter with the appropriate specifications for pressure and temperature that match the intended application environment.

Flow meters need to be selected with consideration for their maximum and minimum temperature and pressure ranges to ensure they match the application’s requirements.

The structural strength and material of a magnetic flow meter’s housing are also influenced by the fluid’s temperature and pressure.

Installation Considerations

Magnetic flow meters require careful installation planning to avoid errors caused by upstream and downstream piping obstructions such as pumps, elbows, or valves.

Cavitation and velocity distribution disturbances that can affect measurement accuracy are influenced by the location of control valves to the flow meter.

To prevent measurement errors, flow meters should be installed in locations that are free from sources of pulsation.

Well-grounded flow meters are essential for mitigating external magnetic field interference, ensuring reliable signal acquisition and accurate measurements.

Considerations for flow direction, pipe diameter, and avoidance of vibration are necessary to secure optimal performance from the flow meter.

The use of exhaust valves, air collection bags upstream, or regulators downstream can be effective in managing the presence of air bubbles that could compromise flow meter accuracy.

Ensuring that water fills the pipe and installing the sensor at the correct angles as per installation guides helps prevent air bubbles, which can impact the accuracy of the readings.

Troubleshooting Common Magnetic Flow Meter Issues

Proper grounding of magnetic flow meters is essential to ensure correct readings and prevent interference from the liquid’s static electricity.

However, even with the best practices in place, issues may still arise. Here are some common problems and how to troubleshoot them.

Air Bubbles and Coating on Electrodes

Installing a gas-collecting device and an exhaust valve upstream of the flow meter can mitigate issues with air bubbles in cases where changing the installation position is not feasible.

If a magnetic flow meter’s measurement signal fluctuates, cutting the excitation circuit current of the magnetic field can help determine if air bubbles are the cause by observing whether the meter still displays flow and if the signal remains unstable.

When large air bubbles cover the entire electrode of a magnetic flow meter, it can cause an open circuit of the flow signal input and result in output signal fluctuation.

Coating on the electrodes can create a high resistance barrier, which with time might block the current flow between the electrodes, causing the meter to stop registering flow.

Ultrasonic cleaning circuits have been used in the past to prevent the coating of electrodes in magnetic flow meters, and such options are commonly used in industries where the process fluid can cause gradual coating.

Some magnetic flow meters offer hot-tap removable electrodes or a bypass line to facilitate the cleaning of the primary without interrupting the flow.

The orientation of the magnetic flow meter can affect its performance, especially if air bubbles collect around the electrodes in a downward flow, which can isolate them from the process fluid.

In such cases, using a flow tube can help maintain the accuracy and efficiency of the flow meter.

Signal Loss and Interference

Signal loss in magnetic flow meters can result from line splits, degraded insulation, or inverter interference. These causes of signal loss can demand actions like cable checks, part repair or replacement, and potentially changing the equipment location for resolution.

Electromagnetic interference is a significant factor causing signal fluctuation in magnetic flow meters.

To mitigate the impact of electromagnetic interference, it is advised to keep magnetic flow meters away from interference sources.

Add a smart sensor to digitize your analog flow meter

There are both analog and digital flow meters. In the case of analog ones, you might want to upgrade your systems and go digital.

Finding an applicable sensor that converts your analog meter into a smart meter is the most often the most affordable and sustainable option!

The implementation of W-Sensor with magnetic flow meters extends the technical lifetime of traditional analog meters, providing further economic benefits.

Key Features of Waltero’s W-Sensor:

Advanced signal processing technology to improve the detection of flow rates in various conditions

A proprietary algorithm that enhances accuracy over a wide range of flow velocities

A unique sensor design that reduces susceptibility to noise and ensures stable performance.

This design prolongs the technical lifespan of traditional meters by minimizing wear and tear through its non-intrusive measurement method.

Compatibility with Various Meter Types

The W-Sensor is designed to be universally applicable, and capable of integrating with a range of metering devices including water, gas, and electrical meters.

This compatibility allows for retrofitting older systems, extending their operational life and ensuring that functional analog equipment is maximally utilized, in line with Waltero’s philosophy.

Data Transfer Capabilities

Waltero’s W-Sensor utilizes advanced camera technology to accurately capture readings from different types of analog meters including numerical displays, dial indicators, and signal lights.

Equipped with multiple connectivity options including LTE, LoRa, and WiFi, the W-Sensor ensures robust and reliable real-time data transmission.

Seamlessly connecting with monitoring systems, the W-Sensor is capable of transferring the captured analog meter values to enable efficient process control and monitoring.

Environmentally Friendly Solution

The W-Sensor operates with high energy efficiency, utilizing standard batteries that last up to a decade and offer an alternative to plug into power sources, significantly reducing battery waste.

Embracing the use of W-Sensors contributes positively to environmental conservation by limiting energy consumption and unnecessary waste.

Waltero’s philosophy of maximizing the use of functional analog equipment is operationalized through the integration of W-Sensors, mitigating the need for premature disposal of such devices, thus proving beneficial for our planet.

5 Frequently Asked Questions on Magnetic Flow Meters

1. What is the working principle of a magnetic flow meter?

The working principle of a magnetic flow meter is based on Faraday’s Law of Electromagnetic Induction, where the fluid’s flow through a magnetic field induces a voltage across the liquid to measure the fluid flow.

2. What are the types of magnetic flow meters?

Magnetic flow meters come in various types, such as insertion and low-flow magmeters, to suit different measurement needs based on pipe size and flow rate. Choose the type that best fits your specific requirements.

3. What are the advantages of implementing magnetic flow meters?

Implementing magnetic flow meters offers advantages such as resistance to aggressive chemicals, adaptability to measure various liquids, and compatibility with a range of pipe sizes and materials, making them versatile for industrial applications.

4. What are the key features of Waltero’s W-Sensor?

The key features of Waltero’s W-Sensor include advanced signal processing technology, a proprietary algorithm for enhanced accuracy, a unique sensor design for stable performance, and compatibility with a broad range of meter types.

5. What should be considered when selecting a magnetic flow meter?

When selecting a magnetic flow meter, consider the working temperature, pressure, flow rate, and velocity, along with the output type and cost-performance trade-offs. These parameters will help you choose a suitable magnetic flow meter for your application.

Summary

In conclusion, magnetic flow meters, with their ability to accurately measure flow rates in different conditions, offer immense benefits in a range of industrial applications.

The integration of advanced technologies like Waltero’s W-Sensor further enhances the functionality and longevity of these devices, ensuring cost-effectiveness and environmental sustainability.

With their versatility, durability, and high performance, magnetic flow meters are indeed revolutionizing the way industries measure and control flows.

As we venture further into the future, these devices, with their innovative features and capabilities, will continue to play a pivotal role in driving efficiency and sustainability in various sectors.